Practical tools for professional smoothing of sealants

Grouting like a master with the FugenMeister

We bring joints into shape

You have already worked with silicone or acrylic and are tired of having more sealant on your hands, clothes or anywhere else but where you want it to go?

Your new multifunctional FugenMeister joint smoother in various designs with angles or radii enable you to easily grout with all commercially available permanently elastic sealants, such as acrylates, silicones, polyurethanes, hybrids, MS polymers, according to existing regulations, in masterly execution. Please observe the processing instructions of the manufacturer.

Tedious and costly masking and reworking is no longer necessary.

The patented FugenMeister joint smoother were developed from the necessity to have functional smoothing tools for all areas of application of joint technology and to meet the constantly growing requirements and needs of industry and trade with regard to functionality and regulation.

Instructions for use, possible applications and interesting facts

- Joints must be firm, clean and free of oil and grease. The use of primer is sometimes a prerequisite for a wall-free adhesion of the sealant.

- Cut the nozzle of the sealant cartridge diagonally according to the joint width.

- The bead of sealant must be applied evenly with a slight excess, applying the cut-off nozzle at approx. 45°.

- Sealants and auxiliaries must be compatible with the building material to be grouted.

- Start smoothing before the skin of the sealant is formed, see instructions on the manufacturer’s cartridge (plan the work sequence so that smoothing can be carried out within the skin formation time).

- If necessary, spray the sealant with a commercially available smoothing agent or apply with a brush, as the sealant can no longer adhere to the adjacent surfaces and can thus be removed much more quickly and cleanly. This means that the sealant inevitably always slides onto the stencil.

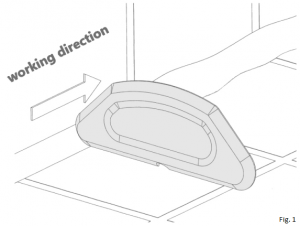

- Select the smoothing tool with the desired geometry, apply cleanly and remove quickly. Make sure that the tool remains in the same position. The flat side of the smoothing tool should always point in the working direction. For clarification, see figure 1.

- When using radius joint smoother a slight smoothing with a damp finger should be carried out after removing the smoothing tool, in order to level out any chatter marks or indentations in the area of the cement joints of tiles.

Of course, 45° joints can also be smoothed slightly afterwards, the resulting geometry will not be significantly changed. - If air bubbles appear, it is advisable to skim the joint again using a smaller joint smoother. If this is not possible and the sealant has not been wetted with a smoothing agent, the joint can be reworked. If a smoothing agent has been used, the sealant must be pulled out partially or completely using the 90° tool. This rarely occurs when the sealant is applied from the right and the left and air is trapped. Air can be displaced at the interface by rubbing the sealant with the nozzle.

- At regular intervals, any excess sealant that accumulates on the smoothing tool when it is pulled off should be wiped off in relaxed water or cleaned with toilet paper. Dispose of toilet paper in a previously prepared dirt bucket. Attention: Do not use solvents.

All data are laboratory values and may vary in practice. A certain processing result cannot be guaranteed due to the unmanageable number of sealants and different application situations. Self-trials are generally recommended before starting work.

Application area of the FugenMeister joint smoother

Wherever aesthetic and prescribed sealant joints are required or desired. Preferably in sanitary/moist rooms such as bathrooms, toilets, showers, kitchens, laundry rooms, sauna areas, outdoor pools, indoor pools, balconies, slaughterhouses, canteens, canal constructions, sewage treatment plants, but also in window construction, boat construction, timber construction, prefabricated houses, mould construction, car body and metal construction (clean rooms), aquarium construction, the smoothing tools are used.

Things to know

Wet rooms must be sealed in such a way that the building structure is permanently protected against water damage.

Water penetrating through joints can cause considerable damage unnoticed from the outside.

All connections must be sealed, especially if different building materials are combined with very different physical properties (e.g. floor/wall and connections to sanitary components).

In addition to its technical function, joint sealing in sanitary and damp rooms has important aesthetic and hygienic tasks. It must be fungicidally treated and easy to clean in order to prevent the infestation and spread of mould fungi.

If fungicide-equipped sealants cannot be used for legal reasons (e.g. food law), the applicability of concrete sealants should be inquired from the manufacturer.

Sealant joints should adapt inconspicuously to the overall appearance. For this reason, they are often not as wide as necessary to absorb the movements of the component elastically. Such undersizing, constant water pollution, chemical stress and aggressive cleaning procedures mean that joints exposed to moisture have to be maintained and serviced. They are therefore regarded as maintenance joints with a limited warranty.

Their condition must be checked at regular intervals and the sealant renewed if necessary in order to avoid consequential damage.

Possible applications Forming of 45° angles, radii or the removal of expansion joints. See Figure 1-6